Racking & Storage Solutions

Helping you build a better warehouse

You need high-performing space while controlling long-term costs. Regardless of what type of space you are designing, warehouse and dock configuration can be a challenge. Yet, well-executed storage, shipping and receiving spaces improve efficiency and make companies more profitable.

WE KNOW WAREHOUSES

Whether you're in manufacturing, storage, retail or fulfillment, we understand how materials flow throughout your facility and that warehouse layout directly affects the day-to-day efficiency of operations.

We can partner at each stage of the warehouse layout and planning process, from space utilization and operations workflow, to storage options and aisle layout to create efficient and productive space.

- Warehouse design schematic

- Space utilization planning

- Strategies for efficient traffic flow

- Warehouse equipment options

WAREHOUSE DESIGN

Whether you are building new or just need additional space, there are many cost-effective solutions to manage your space challenges. We will work with you every step of the way to ensure you're getting the best solution. Speak to a Warehouse Design Expert today.

ON-SITE SURVEYS

If you need to modify your current space to maximize efficiency or if you're building new, we can help at any step in the process. We'll come to you for a free, no-obligation site survey to evaluate the space available and what would work best for your goals.

INSTALLATION

We have a network of installation teams throughout the country to provide prompt, expert installation for minimal disruption to your day-to-day output of your business. Our teams have the proper training, insurance and certifications to install projects safely and on-time.

YOU HAVE OPTIONS TO MEET YOUR PRODUCTIVITY GOALS

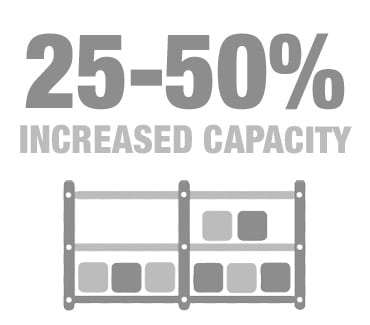

There is no one-size fits all approach to racking and storage. In the best warehouses, you'll see a blend of configurations and solutions to maximize every square inch of available space.

Pallet Flow Racking

With pallet flow racking, you get deep-lane storage and first in-first out (FIFO) control for bulk pallet handling.

- Ideal for high-volume, case-pick applications

- Most commonly use for storing large quantities of pallets of the same product or SKU

- Allows for double storage capacity in the same footprint

Push Back Racking

This racking provides last in-first out (LIFO) storage to maximize capacity of bulk or fast moving products.

- Systems can be rack or floor-mounted

- Cost-effective storage with balance of selectivity and density

- Easily add net or guard systems for additional safety

Selective Racking

Selective accommodates a large number of SKUs while still allowing users to select all pallet loads from the racking without having to move any other pallets.

- Least expensive racking variety available (based on cost-per-pallet position)

- Most commonly used racking system

Case Flow

Case flow racking offers both durability and flexibility for slow moving case storage.

- Ideal for picking full cartons or split-cases

- Provides order picking access to high quantity of SKU locations in relatively small spaces

- Allows for greater pick rates and better overall productivity

Mobile Racking

Mobile racking can reduce or even eliminate wasted space with individual aisle access.

- Standard racking is installed on mobile bases

- Move to open up an aisle for direct access

- Increases capacity up to 100%

Double Wide Drive-In Racking

Designed for maximum space utilization and productivity, with this system you can load and unload two pallets simultaneously.

- Reduces handling costs with fewer aisles

- Increases efficiency and productivity

Mezzanine Floor

Adding a mezzanine floor rack platform system utilizes the height of a warehouse - doubling or even tripling the surface area.

- Most economical option to increase functional space without significant costs of a conventional building expansion

- Adding a mezzanine can often keep you in your current warehouse or distribution center for years longer

SAFE WAREHOUSES CAN SAVE LIVES

Don't undervalue the importance of protecting pallet racks and annual safety inspections to identify repair work before damage causes extensive problems. Protect your investment and protect your people.

Pallet rack systems are becoming increasingly scrutinized by OSHA, government agencies and insurance companies because racking comes with significant legal liabilities. Yet, far too often, damaged rack remains in operation, either ignored or mistakenly assumed to be safe.

Rack systems deal with heavy loads day-in and day-out, so damage can take its toll on even the best racking. These issues can cause:

- costly repairs

- disruption of work

- damage to inventory

- nonproductive downtime

- and even staff injury or death

If you can see damage, your racking systems could already be at a critical tipping point. Just one more impact could push it to collapse.

News & Announcements

Riekes Equipment, a recognized leader in the material handling industry, has been awarded the prestigious MVP (Most Valuable Partner) Award for its outstanding achievements in 2023 by their industry trade…

Read MoreHyster has unveiled two new lithium-ion battery-powered forklifts, the three-wheel J32-40UTTL and four-wheel J30-70UTL. The UTTL is available in capacity ranges of 3,200 lb. (1.5 T) to 4,000 lb (1.8…

Read More